Computers Powered by ‘Memristors’ – Blink!

Posted on September 7, 2010

Filed Under Technology | Leave a Comment

We don’t normally write about computers because lots of other blogs are doing that well. We’re more interested in the processes and products that result from computer-assisted research and innovation. But we like to have a fast computer-at-the ready as much as anyone. So the news about “memristors” begs to be passed along.

Memristors? They’re microscopic devices that promise to allow the continued miniaturization of electronic circuits and extend “Moore’s Law” for decades. You’ll recall that Intel co-founder Gordon Moore predicted in 1965 that the number of transistors that can be added to an integrated circuit would at least double every two years. That, however, could have a limit, before computers will be fast enough to function in “lightbulb mode” – simply on and off, with no startup sequence or even momentary hesitation on tasks.

Memristors? They’re microscopic devices that promise to allow the continued miniaturization of electronic circuits and extend “Moore’s Law” for decades. You’ll recall that Intel co-founder Gordon Moore predicted in 1965 that the number of transistors that can be added to an integrated circuit would at least double every two years. That, however, could have a limit, before computers will be fast enough to function in “lightbulb mode” – simply on and off, with no startup sequence or even momentary hesitation on tasks.

Until now. Alan Boyle, msnbc.com science editor, writes about memristors, the anticipated extenders of transistors, on msnbc’s Cosmic Log blog. Hewlett Packard, Boyle reports, just announced “a collaboration with memory-chip maker Hynix to get the first memristors to market in three years. One of the first goals will be to create a computer you can ‘turn on and off like a light bulb,’ said Stan Williams, founding director of HP Lab’s Information and Quantum Systems Laboratory. But that’s just the beginning.”

Here’s the definition you’ve been waiting for: “Memristors, or ‘memory resistors,’ take advantage of the fact that passing electrical current through particular types of material will change the molecular structure of that material so that it ‘remembers’ which way the current was running, and at what voltage, even when the power is turned off.”

Three years or so till computers that work in the blink of an eye…on-off-on, just that fast. Memristors figure to enable them to function virtually instantaneously, from startup on through.

Now that’s it’s assured that we’ll have all the processing power for whatever we can envision designing and building, we can get on with figuring out how to meet the world’s most pressing needs. We recommend Alan Boyle’s memristors piece, which includes a You Tube video with Stan Williams, as an encouraging prompt into the future. – Doug Bedell

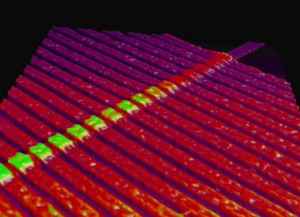

– Photo: A circuit with 17 memristors was captured by an atomic force microscope. By R. Stanley Williams/HP Labs

Comments

Letdowns From Inventive Heights

Posted on September 1, 2010

Filed Under Business, Technology | Leave a Comment

Inventors often feel they are in the service of a higher goal than cleverness, but sometimes ingenuity has to be based on more than good intentions. This thought occured to us on reading in The New Yorker, as the anniversary of 9/11 approaches, of the Rescue Reel. This is a well-meaning device, created at a cost of $335,000 in the inventor’s personal savings, for letting people down from skyscrapers when it’s not possible to take an elevator or even the stairs.

Unless the $1,500 purchase price can be reduced considerably, or building codes in major cities become further sources of inflation, the Rescue Reel would seem to have limited potential, despite its cleverness. Its inventor, Kevin R. Stone, a California orthopedic surgeon, visited The New Yorker’s offices recently to describe how the device works, after explaining that he was deeply moved by the fate of the people trapped on the upper floors of the World Trade Center. So much so that he proceeded to develop the Rescue Reel on the model of a fishing reel.

“I remember thinking right then (on 9/11), If I can reel in a four-hunded pound fish, why can’t I reel out a four-hundred pound person?” Well, most of the panicked people would weigh less than that, a factor in favor of relieving stress on the mechanism, at least.

We get stressed thinking that a skyscraper descent system – down the exterior of a glass-walled tower – might even be needed again. Possibly so, but heaven help us if that’s the case. What needs to be learned from 9/11 is how to provide security against an attack on an office tower, and the Transportation Security Administration (TSA) has been doing a pretty good job of that at the nation’s airports. Also, we’re fighting a war to dissuade any further aerial terrorism. Maybe that won’t do it, but how many people can you picture letting themselves down the outside of a burning, smoke-belching skyscraper? Or even one in which the elevators are merely stuck, and you don’t feel like walking down all those stairs?

We get stressed thinking that a skyscraper descent system – down the exterior of a glass-walled tower – might even be needed again. Possibly so, but heaven help us if that’s the case. What needs to be learned from 9/11 is how to provide security against an attack on an office tower, and the Transportation Security Administration (TSA) has been doing a pretty good job of that at the nation’s airports. Also, we’re fighting a war to dissuade any further aerial terrorism. Maybe that won’t do it, but how many people can you picture letting themselves down the outside of a burning, smoke-belching skyscraper? Or even one in which the elevators are merely stuck, and you don’t feel like walking down all those stairs?

As The New Yorker puts it: “Providing a Rescue Reel for every office worker and apartment dweller above the reach of a Fire Department ladder would cost billions, yet no more than a tiny number of the devices, presumably, would ever be used; in terms of the greatest likely benefit to the largest number of people, mightn’t a sounder investment be colonoscopies?”

We’re not looking to deter inventiveness in writing this, and we note that Dr. Stone feels the price of Rescue Reels will come down considerably when/if they go into mass production. But all kinds of questions arise if you picture a smoke-filled corridor with dozens of panicked people, and a limited number of Rescue Reels on hand to save some of them. Better that we apply all possible ingenuity to attempting to insure that the ghastly sort of no-exit situation created on 9/11 doesn’t occur again.

Use Rescue Reels, we’d suggest, for making rappelling safer for rock climbers. Though there, it’s the sport that matters, not the assurance of a safe descent. Foreseeable utility needs to accompany inspiration, doesn’t it? – Doug Bedell

Comments

…Ingenuity Circa 1955

Posted on August 31, 2010

Filed Under Technology | Leave a Comment

My colleague Doug’s recent Ingenuity: From Inside Out on the benefits of children learning by taking things apart prompted a recollection from my youth.

I was maybe eight-years-old and my closest friend, Mike, and I loved to play in my father’s garage taking things apart. My dad was a great mechanic who also loved to tinker with old radios and other things he would pick up at junk shops, so there were always lots of interesting projects sitting around on shelves or benches. One day Mike and I found an old farm battery – a big one maybe half the size of a modern automotive battery. It was old and had a paper (light cardboard) wrap with the manufacturer’s graphics and a very curious inscription on the top, something like: “Strike here with hammer to energize battery.” I can remember Mike and me speculating on what possible mechanism could be inside that would require one to hit the battery before using it. We decided to find out.

We took off the cardboard cover but we saw no mechanism – only black gunk that looked like tar. Now we were really curious, so we peeled off the gunk trying to expose the innards. We finally decided to simply smack it with a hammer and find out what happened. We hooked the posts to a flashlight bulb and I drew the straw for smacking honors.

I drew back and hit it a good blow, at which point glass shards flew and clear liquid gushed out and splattered me right in the face. I ran screaming into the house where my mother quickly rinsed me off – my face was a little red but I was none the worse for wear.

As my father later explained, I was rather lucky because what I was splattered with was sulphuric acid. It turns out old farm batteries had to have a long shelf life so they put the acid in a sealed glass container that separated it from the anode and cathode, and then coated the whole thing in bitumen to hold the components together and protect the thin glass container. When the farmer was ready to use the battery he would strike the battery on top, breaking the glass and releasing the acid into the cell to start the electrochemical process. What saved me from more serious injury was that the battery was maybe 25 years old and had lost much of its acidity through age and, presumably, reaction with the glass. That near miss slowed us down a little, but we were soon back in the garage taking things apart.

Notice the kids in the photograph in Doug’s posting – they are all wearing safety glasses. I wonder why Mike and I never thought of that? – Dennis Owen

Comments

Ingenuity: From Inside Out…

Posted on August 26, 2010

Filed Under Technology | Leave a Comment

Here’s a Web source for getting technological inspiration going – Make magazine, tagline: “Technology on Your Time.”

We happened upon the site’s feature on how kids learn by taking things apart, and there was instant recognition of what some kids we know have been up to. Also, why TechRepublic’s “teardown” feature is so popular.

We seem to have an innate fascination for seeing how things fit together, or go together. “Sidewalk superintendents” at construction projects are another example of this proclivity.

We seem to have an innate fascination for seeing how things fit together, or go together. “Sidewalk superintendents” at construction projects are another example of this proclivity.

Not that we’re suggesting that taking things apart that really shouldn’t be taken apart is a good idea (unless you’re adept at putting them back together), but it can be a source of inspiration. And, if the target object – like those at Make’s Robotics Redefined both at Detroit’s recent Maker Faire is dispensable anyway, you have a way to keep kids occupied for hours, while revving up their ingenuity circuits.

They took an old turntable, for instance, and turned it into a geared, rotating candle holder. “What would you do with that?” you ask. That’s not the point. But the answer might well be, “Maybe something.”

There’s been a fair amount of attention lately to America’s innovation standing (is it threatened?), including in Bloomberg Businessweek. Find enough mechanisms for kids to take apart and recombine into something new, however, and we’re likely to be reassured.

Anyhow, Make magazine seems worth following. We might be inspired by its own “insides.” And that, of course, is the editors’ intention. – Doug Bedell

Comments

Titantic Being Visited as Her Centennial Approaches

Posted on August 17, 2010

Filed Under The Writing Life | Leave a Comment

She is a monument to technological genius and chutzpah as well. RMS Titanic has been resting, half buried, on the ocean bottom for 98 years now. Scientists are becoming concerned about how much longer she can withstand the corrosive, or naturalizing, forces that are turning her into a mired denizen of the sea.

On August 22, RMS Titanic, Inc., Woods Hole Oceanographic Institution and a host of other partners will conduct a new dive to the Titanic, the first in six years, to ascertain further how she has been “aging” on the seabed. This visit will be uniquely available to the public, photographed with the latest in undersea 3DHD and 2D cameras. A 3D rendering of the wreck will be created.

We came upon this fabulous mission by stopping at the Creativity-online website. You need to be a paid subscriber to see all that’s available on the Titanic there, but we got some tantalizing glimpses by nosing around before the “paid?” screen took over. Maybe, you, too, will be so fortunate.

We can understand why this work needs support; much has been learned to benefit oceanography and nautical history and engineering from past visits to the site 2.5 miles below the Atlantic’s surface. See what you can find here, and join Creativity for more, if it suits your interests.

We’ll soon be hearing about the Titanic Centennial, and this dive, it appears, will be its herald. There will be coverage on YouTube and Facebook, and who knows what other forms of modern media. Marconi wireless radio brought the news that the unthinkable was happening in 1912. – Doug Bedell

Comments

San Jose Heads Into a Green Future, Really

Posted on August 12, 2010

Filed Under Technology | Leave a Comment

We last wrote about acting decisively either to debunk or apply new technologties, not just announce them and see them seemingly ignored.

Now here’s a city that’s acting decisively in, you might expect it, the Silicon Valley. San Jose, CA, in 2007 announced its “Green Vision” – a 15-year plan that includes reducing per capita energy use by half, becoming a zero waste city, recycling and reusing 100 percent of the city’s water, and moving to 100 percent renewable energy. Right on!

Now here’s a city that’s acting decisively in, you might expect it, the Silicon Valley. San Jose, CA, in 2007 announced its “Green Vision” – a 15-year plan that includes reducing per capita energy use by half, becoming a zero waste city, recycling and reusing 100 percent of the city’s water, and moving to 100 percent renewable energy. Right on!

San Jose’s resolves are especially pertinent because we’ve also been writing about the progress toward launching electric cars. A detriment has been the lack of charging stations along highways and byways. But San Jose is doing someting about that.

The California city recently installed the first of 1,600 planned charging stations in the Bay Area as part of the ChargePoint America program to encourage the use of electric cars – by those who can currently afford the Chevy Volt, the Nissan Leaf or the Ford Focus EV, anyway.

San Jose is aiming to break the chicken-or-egg dilemma over which comes first toward reaching a green future. Encouraged by San Jose’s resolve, Couloumb Technologies, the maker of that city’s first charging station, is expecting to have 4,600 of them around the country by October, 2011, in areas including Austin, Detroit, Los Angeles, New York, Washington, D.C. and Orlando.

San Jose’s first charging station is inside a parking garage, appropriately enough – except, of course, that you’d first have to pay a parking fee to reach it. But who can quibble over a city as resolutely aiming for a greener future as San Jose appears to be?

TechRepublic is the source of the highly informative, amply illustrated web story that’s prompting these acclamations for San Jose and electric car makers. And we ought to give some further credit where credit is due on the road to the future. Couloumb’s $37 million Charge Point America program is funded in part by $15 million from the U.S. Department of Energy under the American Recovery and Reinvestment Act.

Lest we get too enthused about the appearance of these first charging stations, TechRepublic points out that the big deterrent to the adoption of electric cars (other than price) is the need for “bigger, better battery technology.” We’ll try to follow that too, for it appears that we’re actually heading toward a less gasoline-reliant future. – Doug Bedell

Comments

Could We Breathe As If There Were No Factories?

Posted on August 4, 2010

Filed Under Technology | Leave a Comment

We keep hearing about how various solar power approaches are key to our energy and environmental future, yet none seem to be applied all that decisively. Here’s a newly announced approach that should either be debunked or applied resolutely.

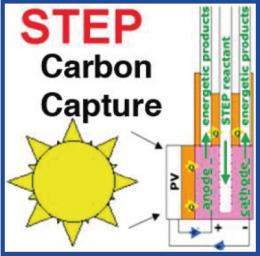

Researchers who have developed the STEP (Solar Thermal Electrochemical Photo) process say it could decrease carbon dioxide in the atmosphere to pre-industrial levels in 10 years. That is, we could have the atmosphere we had before factories, automobiles and trucks started appearing on earth.

Researchers who have developed the STEP (Solar Thermal Electrochemical Photo) process say it could decrease carbon dioxide in the atmosphere to pre-industrial levels in 10 years. That is, we could have the atmosphere we had before factories, automobiles and trucks started appearing on earth.

Why wouldn’t that be considered a goal worthy of priority sponsorship, providing it’s truly feasible? In one continuing STEP activity, we could put the debate over a healthy atmosphere aside; science could triumph.

What is it about announcements that seem so promising, and then aren’t heard about again, at least on a scale sufficient to make a real difference?

In this case, scientists at George Washington University and Howard University, both in Washington DC, and strategic, even, to government, say that “by using the sun’s visible light and heat to power an electrolysis cell that captures and converts carbon dioxide from the air, a new technique could impressively clean the atmosphere and produce fuel feedstock at the same time.”

The new process is described in a paper just published in The Journal of Physical Chemistry Letters. “The significance of the study is twofold,” Stuart Licht, a chemistry professor at George Washington University, told PhysOrg.com. “Carbon dioxide, a non-reactive and normally difficult-to-remove compound, can be easily captured with solar energy using our new low-energy, lithium carbonate electrolysis STEP process, and with scale-up, sufficient resources exist for STEP to decrease carbon dioxide levels in the atmosphere to pre-industrial levels within 10 years.”

So if this is indeed feasible, why don’t we get on with it? Or is our society in a continuing cycle of discussion and debate that keeps promising approaches to environmental goals from being applied not only successfully, but decisively? One would hope not. – Doug Bedell

(Image copyright: Stuart Licht, et al. ©2010 American Chemical Society)

Comments

Memory’s a Dance, Says Dr. Day

Posted on July 30, 2010

Filed Under Business, Technology, The Writing Life | Leave a Comment

Permit us to introduce you to Ruth S. Day, a cognitive scientist at Duke University. Why? Because Dr. Day is doing intensive study of memory, and memory is large where everything begins, in technical writing as well as other fields, not to mention life itself.

Dr. Day has been studying how professional dancers remember their routines. Have you ever thought about that? A modern dance company doesn’t have classical terms for movements, like ballet companies do. So some, like Pilobolus, make up names for the shapes they get their dancer’s bodies into – like “shooting seagulls” or “fat gnomes.” Others, like The Merce Cunningham company, feel that labeling dance moves with words is limiting.

Dr. Day has been studying how professional dancers remember their routines. Have you ever thought about that? A modern dance company doesn’t have classical terms for movements, like ballet companies do. So some, like Pilobolus, make up names for the shapes they get their dancer’s bodies into – like “shooting seagulls” or “fat gnomes.” Others, like The Merce Cunningham company, feel that labeling dance moves with words is limiting.

Memory itself is sort of a dance of associations. Pick your own associations.

“There’s no right or wrong strategy,” Day says, “but certain strategies work better in certain situations and the more memory tools a dancer has, the better. The end goal is not memory in and of itself, but to get past the learning and worrying about it – to do the movement well and enjoy it.”

It all seems to come down to identification and intentionality – identifying what you want to accomplish via a technique or gimmick – anything that works for you – and being intentional about that process.

We’re trying, for instance, to improve our quick recognition of jazz piano passages. And we’re finding that looking at the notes as parts of chords is helpful – that’s a structural approach, rather than a strictly visual one. But what the heck, since it seems to have potential, we’ll try to develop it.

“Whatever works for you,” seems to be a decent memory slogan. The need is to get serious about remembering, and pick your own cues.

Dr. Day has more insights into this subject – What subject was that ? Oh yes, memory – at physorg.com and some further encouragement. We’re glad we’ve met her via the web, and suspect you will be as well. – Doug Bedell

Comments

On Garages as Inspiring Places…

Posted on July 24, 2010

Filed Under Business, Technology | Leave a Comment

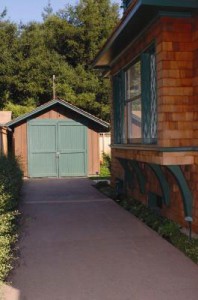

We had occasion to note the entrepreneurial importance of garages as start-up locales in our last Insights post on Andy Grove’s concerns about the status of U.S. manufacturing. One such garage – where Bill Hewlett and Dave Packard got started 70 years ago was designated a national historic landmark in 2007.

We had occasion to note the entrepreneurial importance of garages as start-up locales in our last Insights post on Andy Grove’s concerns about the status of U.S. manufacturing. One such garage – where Bill Hewlett and Dave Packard got started 70 years ago was designated a national historic landmark in 2007.

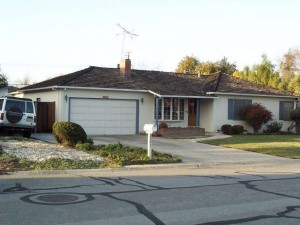

As we happened upon that bit of Internet information, we wondered about the garage where Steve Jobs and Steve Wozniak developed the first Apple computer almost 35 years ago.  We haven’t been readily able to determine its present status, but that garage was part of Jobs’ parents’ home on Crist Drive in Los Altos, CA. (The two Steves actually began creating their revolutionary computer in a spare bedroom, then moved production to the garage.)

We haven’t been readily able to determine its present status, but that garage was part of Jobs’ parents’ home on Crist Drive in Los Altos, CA. (The two Steves actually began creating their revolutionary computer in a spare bedroom, then moved production to the garage.)

Both these garages, of course, are part of the high-tech Silicon Valley story and we normally don’t cover computer technology, because lots of other blogs do. But garages initially aren’t mystical places. They’re handy, available, low-budget spaces with a roof and probably electricity. They only become famous when the ingenuity employed in them proves to be truly visionary.

Even so, we thought you’d enjoy seeing two of the nation’s most famous garages. If your kids want a place to indulge some of their ideas, make yours available. It may become a laboratory setting, a convenient outlet for creativity and, with luck, a source of great wealth. – DB

Comments

Andy Grove ‘Gets Real’ About Manufacturing

Posted on July 18, 2010

Filed Under Business | 1 Comment

What about the continuing drain in American manufacturing jobs? What do we do about it? Why do anything, you say? We still have knowledge creation occurring in the U.S. and that’s what counts.

Well think about it. Andrew “Andy” Grove, co-founder and now a senior adviser to Intel, prompts such salutary thinking in an article – “How to Make an American Job” – in the July 5-11 Bloomberg Businessweek. (We get Bloomberg Businessweek, but we happened upon the Grove article first in surfing the web for technology stories and hitting on the MetalMiner blog. Which demonstrates the unpredictable currents bringing information to our eyeballs these days.)

If we cheer aspiring entrepreneurs operating from garages and other start-up locales, but then send the scale-up and production capacity to China or elsewhere (as we’ve been doing), “What kind of a society are we going to have if it consists of highly paid people doing high-value-added work and masses of unemployed?” A really good and timely question.

If we cheer aspiring entrepreneurs operating from garages and other start-up locales, but then send the scale-up and production capacity to China or elsewhere (as we’ve been doing), “What kind of a society are we going to have if it consists of highly paid people doing high-value-added work and masses of unemployed?” A really good and timely question.

China’s Hon Hai Precision Industry Co. (also known as Foxconn) now employs more than 800,000 people, more, Grove notes, “than the combined worldwide head count of Apple, Dell, Microsft, Hewlett-Packard Co., Intel and Sony Corp.”

Back in 1980, 10 years after it was capitalized for production, Intel had about 13,000 people making computer chips in the U.S. And a host of other companies were sprouting up, and employing Americans, in the Silicon Valley around Intel. But “as time passed,” Grove recalls, “wages and health-care costs rose in the U.S., and China opened up. American companies discovered they could have their manufacturing and even their engineering done cheaper overseas.” So, increasingly, they did. “Today,” Grove points out, “manufacturing employment in the U.S. computer industry is about 166,000 – lower than it was before the first personal computer, the MITS Altair 2800, was assembled in 1975. Meanwhile, a very effective computer -manufacturing industry has emerged in Asia, employing about 1.5 million workers – factory employees, engineers and managers.”

And that’s not just happening in computers. We’ve been writing on Insights about electric cars. Well, their lithium-ion batteries are being made overseas. Not only that, those batteries were developed overseas. When, 30 years ago, the U.S. quit making consumer electronics devices, Grove advises, we lost our lead in batteries too. The scaling took place overseas and now it’s doubtful that U.S. companies “will ever catch up” in battery technology.

When you let something like batteries or photovoltaic panels get away from you, you can lose whole job-creating manufacturing industries. Those guys in the next garages over may never be bright enough to catch up with that.

Bright people need to start thinking keenly about others, our own kids and aspiring workers. Where are they going to be employed a couple of decades from now? It’s a worrisome outlook indeed.

Grove says we need “a job-centric economic theory – and job-centric political leadership to guide our plans and actions. We need specific actions, as well, like financial incentives “to rebuild our industrial commons.” Grove, who grew up in Soviet-dominated Hungary and fled to the U.S. for its opportunities, suggests an “extra tax on the product of offshored labor. (If the result is a trade war, treat it like other wars – fight to win.)”

Yes, you probably sensed where this was heading – we’ve got to start thinking differently about concepts like fair and free trade and where they’ve been taking the economic prospects of growing numbers of Americans. We don’t like “war” metaphors, we don’t want to get nasty, just considerate of what it may take to have people thrive, as they once did, on production lines in the U.S., as well, now, as around the world. – Doug Bedell

Comments

Recently

- Presentations With Forethought

- Technical Writing’s Lineage – Surely It’s Deeper than Digital

- At the Holidays, Twitting Amazon

- Successful Cookie Baking – From Mom, an Acknowledged Expert

- Slides for a Tech Writer’s Craft

- Digital or Not, Be Clear

- Being Watchful About Digital Designs…

- When Proposals Don’t Click, Keep Making Them Anyway

- Like a Good Gardener, Help an Enterprise Keep Itself Current

- We’re Leaders All, And Need to Think That Way

Categories

Archives

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

- April 2011

- March 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- July 2010

- June 2010

- May 2010

- April 2010

- March 2010

- February 2010

- January 2010

Blogroll